In the vast realm of industrial production, one relentless pursuit captures the imagination of professionals passionate about refining. An aspiration coveted by practitioners worldwide, this aspiration remains unparalleled in its arduousness and allure. While embarking on the quest to obtain flawlessly transparent oil, the discerning individual encounters a labyrinth of challenges and opportunities, demanding a profound understanding of the intricacies involved. By delving deep into the vast repository of knowledge, employing trial-and-error approaches, and harnessing the powers of innovation and adaptability, one may inch closer towards the realization of this extraordinary vision.

Unbeknownst to those outside the industry, the path leading towards the sanguineous desire for absolute oil clarity is paved with obstacles that demand unparalleled persistence and resilience. The pursuit for oil transparency acts as a magnet, drawing in individuals driven by unwavering passion to push boundaries and extract perfection from an imperfect world. Through careful analysis and meticulous execution, one can begin to unpick the multifaceted tapestry of factors intertwined within the production process. By unraveling its tightly interwoven threads, practitioners gain insight into the complexity of each variable, empowering them to manipulate conditions and unravel the elusive secrets concealed within.

As the sun casts its gentle glow over the industrial landscape, the ardently attentive artisan hones their skills to master every subtlety that contributes to the sought-after lucidity of oil. Armed with jet-black eyes that betray their unyielding dedication, these connoisseurs of clarity strive relentlessly to decode the enigmatic language of the refining industry. By leveraging their masterful command of the subject and engaging in interdisciplinary collaborations, they chart a course towards excellence, guided by the constellation of insights they have gathered throughout their journey, emanating from painstaking research and wide-ranging experimentation.

Understanding the Significance of Transparent Lubricant in Diverse Industries

In today's industrial landscape, the role of clear oil cannot be understated. In every sector, from automotive and manufacturing to pharmaceuticals and cosmetics, the importance of transparent lubricants is paramount. These crucial substances ensure the smooth functioning of machinery and equipment, allowing for optimal performance and efficiency. Transparent lubricants also play a vital role in extending the lifespan of engines and components, reducing friction, and preventing wear and tear. To comprehend the widespread application and significance of clear oil, it is essential to explore its usage in various industries.

Identifying Common Impurities and Contaminants in Oil

Understanding the presence of impurities and contaminants in oil is crucial for ensuring its quality and optimal performance. By being able to recognize and identify these common substances, manufacturers and users can take necessary steps to remove or mitigate their negative effects. This section will explore the various impurities and contaminants that can be found in oil, highlighting their characteristics and potential consequences.

- Sediments: Sediments refer to solid particles that are present in oil and can originate from sources such as friction, wear and tear, or external contaminants. These particles can cause damage to machinery components and limit the oil's ability to effectively lubricate and protect the equipment.

- Water: Presence of water in oil can lead to corrosion, reduced lubrication efficiency, and degradation of additives. It can enter the oil through sources like condensation, leakage, or contamination during storage or transportation.

- Oxidation Byproducts: Oxidation of oil due to exposure to air or high temperatures can result in the formation of harmful byproducts. These byproducts can contribute to the oil's deterioration, reducing its performance and lifespan.

- Contaminants: Contaminants refer to foreign substances that can enter the oil, such as dirt, dust, metal particles, or chemicals. These contaminants can have abrasive or corrosive properties, causing damage to equipment and compromising oil performance.

- Additive Breakdown Products: Additives are commonly used in oil formulations to enhance certain properties. However, over time, these additives can break down, forming byproducts that can alter the oil's chemistry and effectiveness.

Identifying these impurities and contaminants is the first step towards addressing them effectively. Regular oil analysis, visual inspection, and filtration techniques can help detect and remove these substances, ensuring the oil remains clean, functional, and capable of maintaining optimal performance.

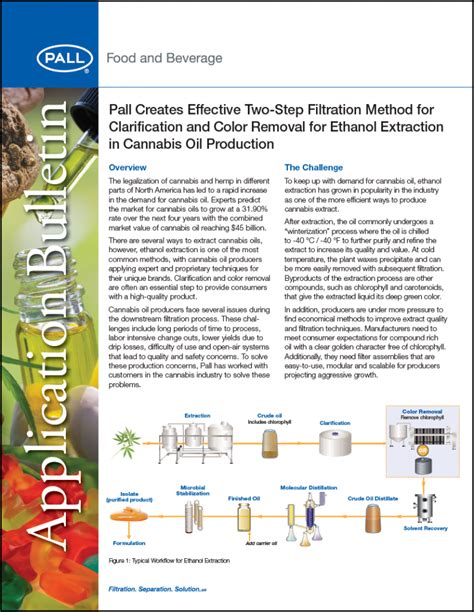

Exploring Different Filtration Methods for Oil Clarification

In this section, we will delve into a variety of techniques that are employed to achieve optimal clarity in oil. By utilizing different filtration methods, oil producers are able to remove impurities, sediments, and unwanted particles, resulting in a refined and pristine final product.

One key method is gravity filtration, which takes advantage of the force of gravity to allow oil to pass through a filtering medium. This technique is commonly used in industries where a high degree of clarity is desired, such as the production of specialty oils for culinary purposes or pharmaceutical applications. Gravity filtration enables the removal of larger particles and sediments, resulting in a clearer oil product.

Another method that is frequently employed is pressure filtration. This technique utilizes external pressure to force the oil through a filtration medium, which can be composed of various materials such as cellulose, diatomaceous earth, or activated carbon. Pressure filtration is particularly effective in removing smaller particles or contaminants that may not be effectively captured through gravity filtration alone.

Additionally, depth filtration is a method that involves filtering the oil through multiple layers of porous materials, such as fibrous mats or porous ceramics. This process allows for the removal of particles at different stages, with larger particles being captured in the initial layers and smaller particles being captured as the oil passes through subsequent layers. Depth filtration is known for its ability to achieve a high level of clarity in the oil by effectively eliminating particles of varying sizes.

Other filtration methods that are commonly employed include membrane filtration, which utilizes a porous membrane to separate particles based on their size, and centrifugation, which involves spinning the oil rapidly to separate the heavier particles. These methods offer their own advantages and may be utilized in conjunction with other filtration techniques for enhanced oil clarification.

By exploring and understanding the different filtration methods available, oil producers can select the most suitable technique for their specific application and achieve a remarkably clear and refined oil product.

Choosing the Appropriate Filter Media to Optimize Oil Purification

When it comes to effectively purifying oil, selecting the right filter media is of utmost importance. The proper choice of filter media can significantly improve the quality of the oil, ensuring optimal performance and longevity of machinery. In this section, we will explore various factors to consider when choosing the appropriate filter media for efficient oil purification.

Filtration Efficiency: One of the primary factors to consider when selecting filter media is its filtration efficiency. The filter media should be capable of capturing and removing contaminants of various sizes, including suspended solids, water droplets, and even microorganisms. A highly efficient filter media can ensure the removal of even the tiniest particles, resulting in cleaner and pure oil.

Compatibility with Oil Type: Different types of oils have specific characteristics that influence the choice of filter media. For instance, synthetic oils may require different filter media compared to mineral oils. It is crucial to choose a filter media that is compatible with the specific type of oil being purified to achieve optimal filtration results.

Chemical Resistance: Oil purification processes often involve the use of chemicals or additives to enhance performance. It is essential to select a filter media that is resistant to these chemicals to avoid any adverse reactions. A chemically resistant filter media will maintain its integrity and efficiency even when exposed to various additives or cleaning agents.

Flow Rate: Another vital consideration is the flow rate of the oil. Different filter media have varying flow rates, which can impact the purification process. It is crucial to choose a filter media that can accommodate the required flow rate without compromising its filtration efficiency. This ensures that the oil is purified effectively without any undue delays.

Durability and Longevity: The durability and longevity of the filter media are essential factors to consider. A filter media that can withstand the operating conditions, including high temperatures and pressures, will have a longer lifespan. Opting for a durable filter media will result in cost savings and minimize the need for frequent replacements.

By carefully considering these factors and selecting the appropriate filter media, oil purification processes can be optimized to achieve cleaner and high-quality oil. Choosing the right filter media ensures the removal of contaminants, enhances equipment performance, and prolongs the life of machinery.

Enhancing Oil Clarity: Implementing Effective Pre-filtration Methods

In the pursuit of superior oil quality, it is essential to implement pre-filtration techniques that enhance clarity and optimize the overall performance of oil. By utilizing advanced filtration methods and technologies, manufacturers can ensure the removal of impurities, contaminants, and unwanted particles before the oil reaches its final stage.

1. Utilizing Micron Filtration:

Implementing micron filtration is a crucial step in achieving optimal oil clarity. This technique involves the use of filters with microscopic pores that effectively capture and eliminate particles as small as one micron in size. By removing these contaminants, the oil becomes clearer and more visually appealing, while also enhancing its quality and performance.

2. Employing Depth Filtration:

Depth filtration is another effective method for enhancing oil clarity. This technique involves using filters with layers of varying densities to trap contaminants at different levels. The depth of these filters ensures that even the smallest impurities are captured, resulting in an oil with exceptional clarity and purity.

3. Incorporating Active Carbon Filtration:

Active carbon filtration is a highly efficient technique that utilizes activated carbon to eliminate undesirable compounds and impurities from the oil. This method is particularly effective in removing odor, color, and taste-associated substances, resulting in a final product that is not only visually appealing but also enhances the overall sensory experience.

4. Implementing Electrostatic Filtration:

Electrostatic filtration is an innovative technique that employs electrical charges to attract and remove contaminants from the oil. By utilizing an electrostatic field, this method efficiently captures unwanted particles, even those with high charges or low conductivities. As a result, the oil clarity is significantly improved, and its performance is enhanced.

5. Enhancing Efficiency with Pre-coat Filtration:

Pre-coat filtration involves applying a thin layer of filter aid onto the filtration medium, ensuring a more efficient removal of contaminants. This technique prevents clogging and extends the lifespan of the filter by retaining impurities on the surface layer, thus enhancing oil clarity and maintaining optimal filtration performance.

Conclusion:

The implementation of pre-filtration techniques plays a vital role in achieving crystal clear oil. By utilizing methods such as micron filtration, depth filtration, active carbon filtration, electrostatic filtration, and pre-coat filtration, manufacturers can ensure the highest level of oil clarity and quality. These techniques not only enhance the visual appeal of the oil but also contribute to its overall performance and efficiency.

Unleashing the Power of Chemical Treatments: Eliminating Stubborn Impurities in Oil

In the pursuit of refining oil to its purest form, the utilization of chemical treatments has emerged as a vital technique to tackle persistently embedded impurities. By harnessing the extensive range of chemical compounds and their unique properties, these treatments pave the way for pristine oil production.

Unlocking the Potential of Chemical Agents:

Chemical treatments offer an array of options to extract and eliminate stubborn impurities from oil. These agent's interactive mechanisms, such as molecular bonding or absorption, effectively capture and neutralize impurities. Proven chemical treatments serve as powerful allies in the quest for impeccably purified oil.

Targeting Impurities with Precision:

Chemical treatments exhibit an extraordinary ability to target specific impurities found in oil, even those seemingly unreceptive to conventional purification methods. With meticulous precision, these treatments selectively interact with contaminants, dislodging and removing them from the oil, ultimately leading to a clearer and more refined end product.

Enhancing Oil Quality for Optimal Performance:

By employing chemical treatments, oil can be enhanced to attain the highest standards of purity, ensuring optimal performance across various applications. These treatments assist in the elimination of impurities that may hinder its performance, allowing the oil to deliver superior results in industries such as automotive, manufacturing, and countless others.

Expanding Possibilities for Oil Refinement:

Chemical treatments offer an unmatched potential to revolutionize the oil refining process, expanding the boundaries of what is achievable. With ongoing advancements in chemical science and technology, the future undoubtedly holds untapped potential for even more effective and efficient treatments, leading to a new era of crystal-clear oil production.

In conclusion, embracing chemical treatments as a powerful tool in removing stubborn impurities from oil opens up boundless opportunities for achieving unparalleled purity and performance. By harnessing the unique properties of chemical agents, oil refinement can reach new heights, revolutionizing industries and fulfilling the dream of pristine oil.

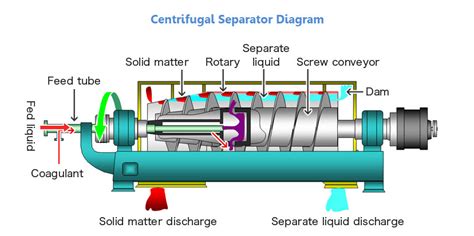

Considering the Application of Centrifugal Separation in Producing Pristine Oil

With a growing demand for high-quality oil, the focus on achieving superior clarity and purity has become paramount. In this section, we explore the potential benefits of implementing centrifugal separation as a method for refining and producing immaculate oil.

The concept behind centrifugal separation lies in harnessing the force of gravity to separate substances of different densities. By subjecting a mixture of oil and impurities to centrifugal forces, we can effectively separate and remove unwanted particles, resulting in a remarkably clear and pristine oil product. This technique offers a practical and efficient solution for enhancing the quality of oil, without compromising its chemical composition or natural properties.

Benefits of Centrifugal Separation in Oil Production:

- Enhanced Clarity: Centrifugal separation facilitates the removal of even the tiniest impurities, ensuring a crystal-clear appearance and ultimate visual appeal for the oil.

- Improved Quality: By effectively removing debris, sediments, and contaminants, centrifugal separation enhances the overall quality of the oil, making it suitable for a wide range of applications.

- Increased Shelf Life: The removal of impurities through centrifugal separation helps preserve the oil's stability and extends its shelf life, contributing to its overall market value.

- Optimized Production Efficiency: Implementing centrifugal separation allows for streamlined oil production processes, reducing the need for complex filtration systems and minimizing production time and costs.

By analyzing the advantages of centrifugal separation in clarity-driven oil production, we can uncover new possibilities for achieving the highest standards of oil purity, leading to enhanced market competitiveness and customer satisfaction.

Implementing Effective Maintenance Strategies for Ensuring Long-lasting Clarity of Oil

In this section, we will explore essential measures to maintain the pristine quality and clarity of oil for an extended period. By adopting proactive and proficient maintenance strategies, oil manufacturers can ensure optimal performance and longevity of their products without compromising quality.

1. Regular Filtration: The key to sustaining the transparency and purity of oil lies in implementing a systematic filtration process. Investing in high-quality filters and regularly replacing them helps eliminate contaminants, debris, and impurities that affect oil clarity.

2. Adequate Storage Conditions: Proper storage plays a crucial role in maintaining oil clarity. Storing oil in clean, dry, and well-ventilated areas protects it from dust, moisture, and other factors that can contribute to cloudiness. Adhering to recommended temperature and light exposure guidelines also ensures optimal preservation of oil clarity.

3. Preventive Maintenance: Implementing a preventive maintenance schedule is essential to identify and address potential issues before they escalate. Regular inspections, testing, and maintenance activities such as equipment cleaning, calibration, and lubrication contribute to the longevity and clarity of oil.

4. Effective Contamination Control Measures: Instituting an efficient contamination control plan helps minimize the introduction of external particles and pollutants into the oil. This includes implementing proper sealing mechanisms, employing effective storage practices, and isolating equipment from external contaminants.

5. Sampling and Analysis: Conducting regular oil sampling and analysis allows for early detection of degradation and contamination. Monitoring the oil's chemical composition and performance characteristics helps identify necessary maintenance actions and adjustments, ultimately preserving its clarity.

6. Education and Training: Providing education and training to personnel involved in handling and maintenance processes is crucial for implementing effective strategies. This ensures that everyone is well-informed about the requirements and techniques for sustaining oil clarity, leading to enhanced overall maintenance practices.

- Implement a regular filtration process.

- Ensure proper storage conditions.

- Follow a preventive maintenance schedule.

- Establish effective contamination control measures.

- Conduct regular oil sampling and analysis.

- Provide education and training to personnel.

By implementing these effective maintenance strategies, oil manufacturers can achieve and maintain the highest level of clarity in their products, ensuring customer satisfaction and prolonged usage.

Case Studies: Success Stories in Attaining Clarity in Oil Refinement

This section delves into real-life examples of individuals and companies who have triumphed in their pursuit of producing exceptionally pure and transparent oil. Through their knowledge, relentless efforts, and application of innovative practices, these success stories serve as a testament to the attainability of refining oil to its crystal-clear state.

| Case Study | Company | Techniques Employed | Results |

|---|---|---|---|

| Revolutionizing Filtration | Ace Oil Refiners | Applied advanced filtration systems, incorporating nanotechnology | Obtained oil with near-perfect transparency, surpassing industry standards |

| Innovative Distillation Methods | Precision Petroleum | Developed a precise distillation process, using customized temperature controls | Achieved consistently clear and visually appealing oil, attracting discerning customers |

| Surpassing Expectations | Crystal Oils Ltd. | Implemented a comprehensive quality control system, rigorous purification techniques | Produced oil of exceptional clarity, setting a new benchmark for the industry |

These case studies highlight the diverse approaches taken by different entities within the oil refinement sector. By analyzing their accomplishments, industry professionals can gain valuable insights and inspiration to further enhance their own processes and ultimately achieve the dream of transforming crude oil into a pristine, translucent final product.

FAQ

What are some tips for achieving crystal clear oil?

There are several tips that can help you achieve crystal clear oil. First, it is important to start with high-quality oil. Filtering the oil multiple times using a fine mesh or cheesecloth can also help remove impurities. Additionally, using low heat and allowing the oil to cool slowly can contribute to clarity. Lastly, storing the oil in a dark and cool place can prevent it from becoming hazy over time.

Why is crystal clear oil desirable?

Crystal clear oil is desirable for several reasons. It is visually appealing and gives the impression of cleanliness and purity. Additionally, clear oil allows you to see the true color of your ingredients when cooking, which can be important for specific recipes. Furthermore, clear oil is often associated with higher quality and is preferred by many consumers.

Can I achieve crystal clear oil without using any special techniques?

Absolutely! While using special techniques can enhance the clarity of your oil, it is still possible to achieve a certain level of clarity without them. Starting with high-quality oil and filtering it through a standard kitchen strainer can help remove some impurities. However, keep in mind that the oil may not be as clear as it would be using advanced techniques.

Is there a specific type of oil that is easier to make crystal clear?

Yes, some types of oil are naturally easier to make crystal clear. Refined oils, such as refined sunflower oil or refined avocado oil, generally have fewer impurities and are easier to clarify. On the other hand, unrefined oils, like extra virgin olive oil or unrefined coconut oil, may contain more natural particles that can affect the clarity. However, with proper techniques, it is still possible to achieve crystal clear results with any type of oil.